The challenge of in-orbit assembly in Europe

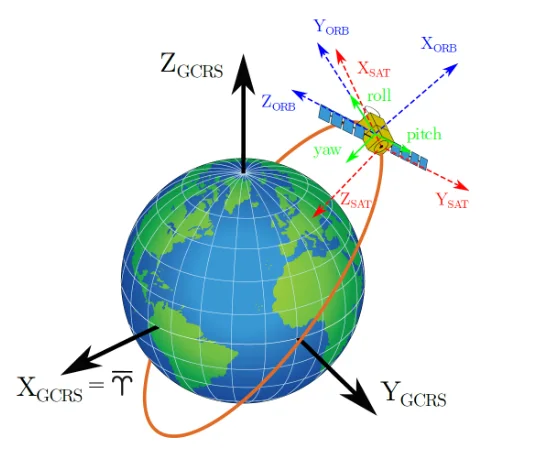

The various space projects implemented or in production in Europe in recent years require increasingly complex robotic intervention capabilities in constrained environments, sometimes without direct human assistance. This is why in-orbit assembly is one of the major challenges facing the space industry over the coming decades.

In this context, Magellium Artal Group is involved in several European projects aimed at simulating, planning and supervising future operations. From on-board robotics to in-orbit assembly, the Group is leveraging its expertise in robotic applications and 3D simulation to propose concrete solutions.

In-orbit assembly, the future of space robotics

Several of the Group's projects are part of this dynamic.

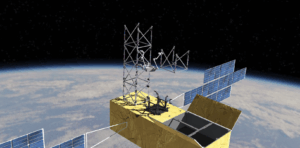

PULSAR is a benchmark. This European H2020 project, coordinated by Magellium Artal Group in partnership with GraalTech, CSEM, DLR, DFKI, Space Applications Services, ONERA and TAS-F, aims to develop the technologies needed to assemble large optical telescopes directly in orbit. The aim is to enable autonomous handling of large components via coordinated robotic systems. Magellium Artal Group has developed a complete simulator capable of representing the space environment, the various operations to be carried out and the interactions between sub-systems.

The ISAAC project is anESA project led by Airbus Defence and Space UK (in collaboration with Airbus Defence and Space France and Germany, Magellium Artal Group and Cranfield University). It aims to demonstrate the autonomous assembly capabilities of a structure: a robot is equipped with three manipulator arms capable of moving over the surface of the structure to extend it. The project's development includes the design of the structure's constituent parts and the definition of the ConOps (concept of operations) for assembling them, the planning of robot trajectories, the simulation of operations for validation and the development of a GCS (Ground Control Station) for robotic operations to control execution.

The project EU-RISEproject, a European Horizon Europe project coordinated by Airbus Defence and Space Gmbh, brings together several European partners(DFKI, Libre Space Foundation, The Exploration Company, Sener, Airbus Defence and Space Fra,ce and UK, Oiko+ and Magellium Artal Group) to design a complete ecosystem for autonomous assembly and maintenance robotics in space.

Finally, the DEMARLUS project takes technology even further in complex situations.

DEMARLUS, taking space robotics one step further

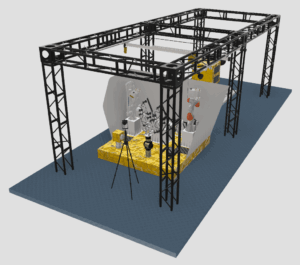

The France 2030 DEMARLUS project, run by The Exploration Company (TEC) with Airbus Defence and Space France, features a ground-based robotic demonstrator. It reproduces the constraints of TEC's "NYX" capsule to experiment with a robotic assembly scenario in orbit via a digital twin.

The aim of the project is to demonstrate the technical feasibility of autonomous on-orbit assembly of complex structures in a space environment.

To achieve this goal, each project partner is contributing its own expertise. The Exploration Company is providing the orbital platform and logistics, Airbus Defence and Space is contributing its skills in onboard robotics, and Magellium Artal Group is designing the digital twin and the simulation environment for planning and supervising operations.

The reference scenario is based on a "factory", an autonomous factory integrated into the Nyx capsule, made up of several robotic arms capable of carrying out a wide range of assembly and handling operations. From the ground, operators can plan sequences, simulate trajectories and monitor progress in real time via a supervision interface (GUI, replanning, logs).

On the technical side, the demonstrator is based on our GAIA simulation environment, a framework for controlling robotic arms, integrating simulation and 3D kinematics tools. This configuration of the digital twin enables sequences to be tested, collisions to be anticipated and actions to be adjusted according to the state of the system or sensor feedback.

The whole process takes place in two stages: first, complete simulations enable us to virtually reproduce the course of a real mission in orbit, and to assess the associated constraints. These scenarios are then replayed in near-real conditions on the ground, in a physical robotic environment synchronized with the digital twin.

This demonstration confirmed the system's ability to perform autonomous and robust space assembly operations.

Towards the next generation of in-orbit robotic operations

The other projects in which we are involved aim to push back the limits of space robotics. Each shares a common thread: integrating simulation, control, perception and supervision into a single chain. This modular approach makes it easier to move from one project to another, and speeds up the response to new needs in onboard space robotics.

Through these projects, the digital twins and simulation, we're mobilizing all our know-how in the service of future orbital missions.

Our expertise puts us in a position to prepare today for future in-orbit assembly and maintenance operations, while supporting the transition to greater autonomy for space robotics systems.